Turn Your Project into Reality with Skilled Plastics Processing

We can build your molds, manufacture your products, and ship them to your customers with our extensive plastics processing services. Backed by more than 60 years of experience delivering excellent results, our structural foam molding services empower our customers with greater moldability, cost-effectiveness, and durable yet lightweight parts. Our structural foam molding process allows us to produce parts with a typical wall thickness range of .250” to .500”.Learn More

Custom Plastic

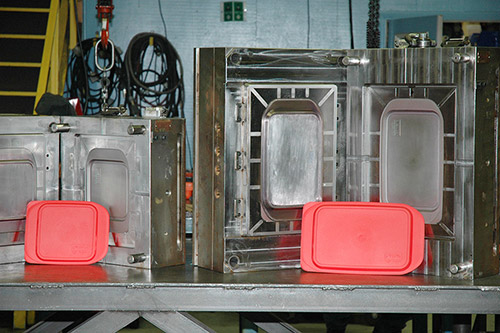

Injection Molding

We are experienced in molding virtually any thermoplastic including ABS, HDPE, LDPE, polystyrene, polypropylene, polycarbonate, PVC, HIPS, Delrin, polysulfone, and PEEK.

Injection Mold Fabrication

At Port Erie Plastics, we know what it takes to compete with Asian mold builders. We can produce single and multi-cavity molds, as well as stack molds and hot runners.

Structural Foam

and Extrusion

Our structural foam molding process allows us to produce parts with a typical wall thickness range of .200” to .500”.

Engineering and

Automation

Our engineers help make projects more cost effective, more efficient, advise on new designs, or suggest modifications.

Secondary

Operations

Port Erie Plastics offers a wide array of assembly and decorating services as part of our turnkey manufacturing solutions.

Distribution and

Warehousing

We offer complete warehousing and distribution services, providing our customers with a single source solution for all logistical requirements.

Plastic Pallets

The Skidmarx® plastic pallet is affordable enough to use as a one-way pallet, yet durable enough to get repeated use in the right situation.

World Class Facility and Expertise

Our manufacturing and warehousing complex now encompasses 615,000 square feet on 69 acres - housing nearly 90 injection molding machines and about 400 full-time employees.molding

machines

tool room

fulfillment