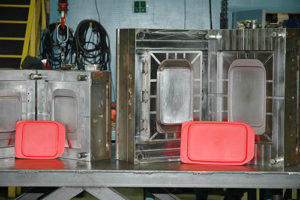

Our customer, a large kitchen products OEM, had the opportunity to land a huge promotional order. The deal called for delivering 3 million pieces of glass bakeware with plastic lids in a five month window. The bid called for 2 million 8×8 dishes and 1 million 9×13 dishes. However, only one single-cavity lid mold existed for each lid shape. Those molds could produce fewer than 700,000 pieces each in the available delivery window running 24/7, and that wouldn’t be the only demand for those lids in that timeframe. So, Port Erie delivered six brand new molds, the first three in less than eight weeks, and at least one more mold every two weeks until all the new molds were in production. And, we did this in the Thanksgiving – New Year’s timeframe. During the last 30 days, we were running 8 lid molds 24/7. In addition, we negotiated for 1 million pounds of resin at a fixed price in the face of a resin market that saw polypropylene rise by 23%.

Our customer, a large kitchen products OEM, had the opportunity to land a huge promotional order. The deal called for delivering 3 million pieces of glass bakeware with plastic lids in a five month window. The bid called for 2 million 8×8 dishes and 1 million 9×13 dishes. However, only one single-cavity lid mold existed for each lid shape. Those molds could produce fewer than 700,000 pieces each in the available delivery window running 24/7, and that wouldn’t be the only demand for those lids in that timeframe. So, Port Erie delivered six brand new molds, the first three in less than eight weeks, and at least one more mold every two weeks until all the new molds were in production. And, we did this in the Thanksgiving – New Year’s timeframe. During the last 30 days, we were running 8 lid molds 24/7. In addition, we negotiated for 1 million pounds of resin at a fixed price in the face of a resin market that saw polypropylene rise by 23%.

Outcome:

3 million lids delivered ahead of schedule.