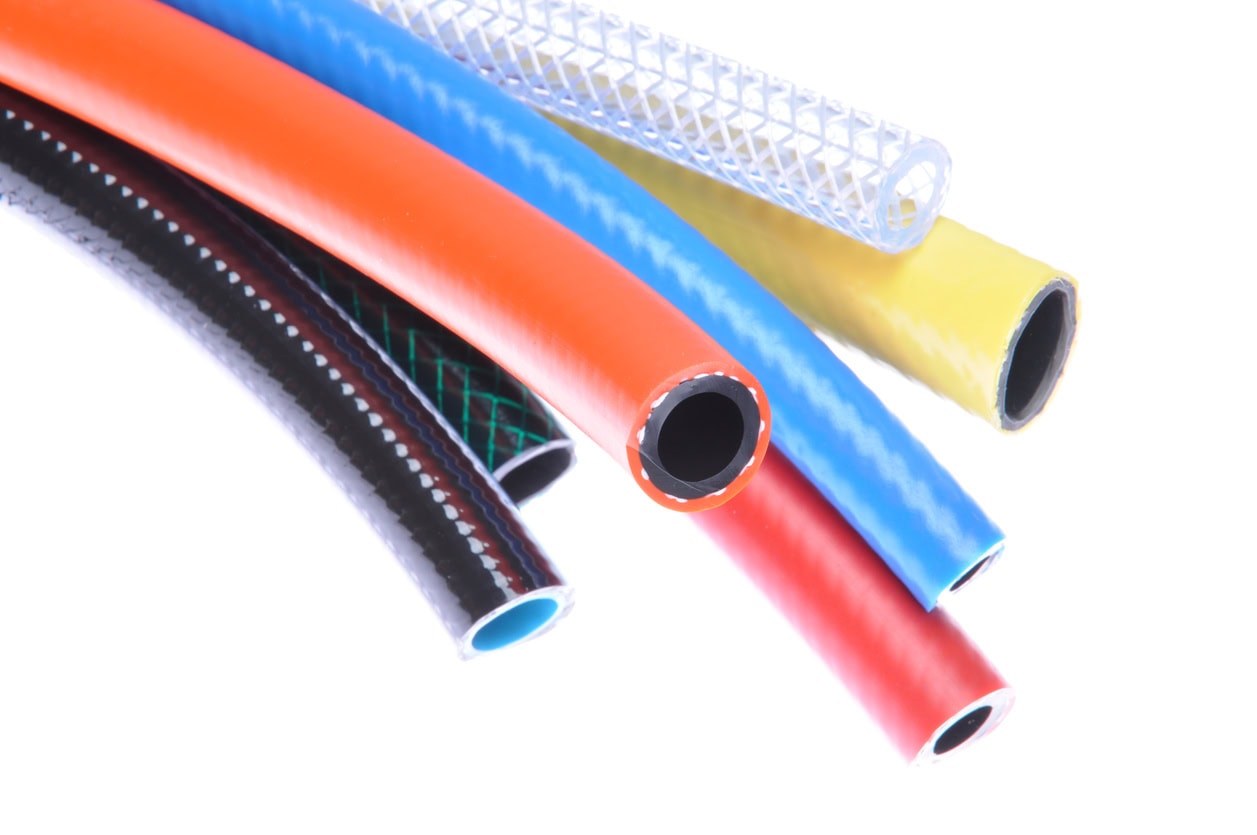

At Port Erie Plastics, our captive operations capabilities are designed to support customers with complex needs. For almost two decades, we’ve been running extended tube products from ¼” to 4”. And with 70 years of experience in plastics manufacturing, we’re able to meet all your extrusion needs. Whether you’re looking to streamline manufacturing, improve product consistency, or consolidate vendors, we make it easy.

If you’re looking for a partner to take on your captive operations extrusion, please contact our team!

Full-Service Extrusion Capabilities

Our captive operations lines are built to handle a wide range of products and volumes, giving you the flexibility to scale as needed, without compromising quality.

- 3.5” screw, 28:1 L/D barrier screw — estimated 500 lbs/hour of HDPE

- 120 mm screw, 30:1 L/D barrier screw — estimated 800 lbs/hour of HDPE

- 3.5” screw, 30:1 L/D barrier screw — estimated 500 lbs/hour of HDPE

With 60-80 feet of cooling space, 12×12 vacuum and spray tanks, and precision pullers with a 4.5” max feed opening, we ensure your product stays consistent and within spec from start to finish. Additionally, our servo flywheel cutters, upcut saws, and master reel recoiling equipment ensure your product is handled with consistency and precision. We also offer multi-layer tube capabilities (up to three layers) to meet your product performance requirements.

Advanced Quality and Material Control

When you partner with us, you avoid the costly setbacks of inconsistent extrusion. Our systems are designed for accuracy and repeatability, so you can focus on the bigger picture.

- 360-degree ultrasonic OD and wall thickness monitoring (up to 2” and 3.5” depending on the line)

- Blending of up to three solid components, with every gram weighed during blending

- Material drying capabilities to prevent moisture-related defects

- Continuous inkjet printing (up to 6.6 m/s) for traceability and branding

And with our in-house toolroom, we can design and build custom extrusion tube dies to support your project from concept through production.

Port Erie Plastics is Here to Discuss Your Captive Operations Extrusion

With over 70 years of experience, Port Erie has the experience, knowledge, and equipment needed to take on a variety of plastics projects. Our capabilities in automated injection molding, custom injection molding, and structural foam molding allow us to create small, medium, and large parts. Our secondary operations ensure your products are finished to your specifications, and our warehousing and distribution services take the burden off your shoulders.

Our team provides processing expertise from start to finish. We offer engineering services to ensure your product is designed for efficient manufacturing. From there, we can create the molds and tooling needed for your production process. Contact our team to learn more.