Port Erie Plastics has provided custom plastic injection molding services for over 60 years. This extensive experience, combined with our mold design and tooling transfer capabilities and a broad selection of thermoplastics and materials, enables us to accommodate a wide range of injection molding needs. By offering customers a variety of material options, we make it possible for them to choose one that meets their exact specifications and standards.

Our Thermoplastics & Materials

Below, we highlight the materials we can use in our injection molding process.

Acrylonitrile-Butadiene-Styrene (ABS)

Acrylonitrile-Butadiene-Styrene (ABS) are low-cost thermoplastics that readily accommodates fabrication, machining, and thermoforming. It exhibits excellent strength and stiffness as well as resistance to abrasion, chemicals, creep, heat, impact, and stress. However, extended exposure to sunlight can cause changes to surface color, gloss, hardness, and impact strength. Typical uses include components for automobiles, food processing equipment, and plumbing systems.

Acetal/Delrin®

Acetal—also known as polyoxymethylene—offers a unique combination of low friction, high wear resistance, strength, and stiffness that make it a suitable replacement for metal in many applications. It has excellent dimensional stability, a broad operating temperature range, and good colorability. It can be used to make components for conveyors, doors, medical devices, and more.

High-Density Polyethylene (HDPE)

High-density polyethylene (HDPE) offers higher tensile strength but lower stiffness than other polyethylene materials. It also exhibits resistance to various chemicals, including excellent resistance to solvents, very good resistance to alcohols and diluted acids/alkalis, and good resistance to oils and greases. Other key properties include good processability, low-temperature resistance, and electrical resistivity. Typical uses include consumer goods, packaging, and pipes and fittings.

Low-Density Polyethylene (LDPE)

Low-density polyethylene (LDPE) is less strong and stiff than HDPE, which makes it more flexible. This quality makes it suitable for making flexible parts and products, such as packaging bags, films, and bottles. Its plasticity and low water absorption also make it one of our thermoplastics well-suited for pipes and fittings.

Nylon

Nylon is a synthetic material that is highly versatile, durable, and flexible, making it a low-cost alternative to materials such as rubber, silk, and latex. Other key advantages include high melting temperature, low frictional properties, high tensile strength, and good resistance to abrasion and chemicals. It is commonly used in injection molding operations but can be used in other manufacturing processes. Typical uses include components for high-friction machinery such as automobile engines.

Polyetheretherketone (PEEK)

Polyetheretherketone (PEEK is a high-performance material with excellent chemical resistance, mechanical strength, and dimensional stability. It also has good hydrolysis resistance and thermal resistance. These qualities make it suitable for countless applications, including components for the aerospace, food processing, medical, pump and valve, and semiconductor industries.

Polycarbonate (PC)

Polycarbonate plastics are strong and tough thermoplastics. It has excellent stiffness, dimensional stability, and thermal resistance. It can be used to create plastic components such as brackets, covers and housings, electrical connectors and insulations, lenses, and medical tubes.

Polyester (PET)

Polyester—also known as polyethylene terephthalate (PET)—is a versatile and durable thermoplastic. It has good strength, stiffness, toughness, and chemical resistance. It can be used in a number of manufacturing operations, including injection molding. Typical components include containers and other packaging.

Polypropylene (PP)

Polypropylene demonstrates good chemical resistance (to diluted acids and bases), elasticity and plasticity, electrical resistivity, and transmissivity. These properties make it ideal for many applications, including product packaging (chemical resistance), electronic components (electrical resistivity), and lenses/windows (transmissivity).

Polystyrene (PS)

Polystyrene (PS) is available in rigid foam and solid plastic forms. The former is used for product packaging filler (e.g., packing peanuts), while the latter is used for components such as cases, cups, enclosures, test tubes. It is low cost, readily available, and easy to work.

Polyphenylsulfone (PPSU)

Polyphenylsulfone (PPSU) is strong, tough, and dimensionally stable. However, it also expensive, which is why it is generally used for applications where these characteristics are critical. One common use is electrical connectors.

Polyvinyl Chloride (PVC)

Polyvinyl chloride (PVC) has an excellent strength-to-weight ratio, hardness, corrosion and weather resistance, and electrical and thermal insulating properties. It can be readily machined, bent, shaped, and otherwise worked into various shapes and sizes. Typical components include pipes and fittings.

Chlorinated Polyvinyl Chloride (CVPC)

Chlorinated polyvinyl chloride (CPVC) has similar characteristics to PVC. However, it offers higher thermal resistance and better machinability and weldability. It is used in different structural applications, including tanks, ventilation systems, and other equipment installations.

Polypropylene (Homopolymer)

Among the vast selection of our thermoplastics, polypropylene demonstrates good mechanical, physical, chemical, thermal, and electrical properties. While it offers less impact strength than HDPE or LDPE, it has better tensile strength and thermal resistance. Additionally, compared to the copolymer variation, the homopolymer variation offers better strength and rigidity.

High-Impact Polystyrene (HIPS)

High-impact polystyrene (HIPS) is a low-cost material offering good toughness, impact resistance, and machinability. It is best suited for low-heat applications where cost is a critical factor.

Don’t see a material listed above? Contact us to see how we can work with you to find an appropriate solution!

Why Are Glass-Filled Plastic Resins Good for Injection Molding?

While the plastic injection molding process accommodates a wide range of materials, there are numerous advantages to choosing glass-filled plastic resins for a project. The primary one is that the addition of glass fibers improves certain properties of the base polymer—strength and rigidity. These qualities are vital for static load-bearing applications.

Some of the plastic resins available with glass-filled options include ABS, acetal, nylon, polycarbonate, PET, and PEEK.

How to Select the Right Thermoplastic or Material

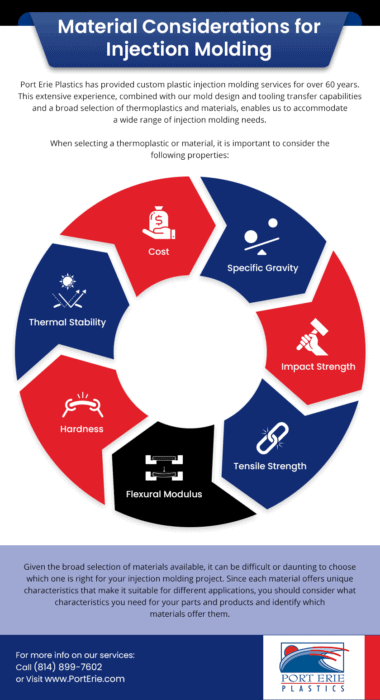

Given the broad selection of materials available, it can be difficult or daunting to choose which one is right for your injection molding project. Since each material offers unique characteristics that make it suitable for different applications, you should consider what characteristics you need for your parts and products and identify which materials offer them.

Some of the key material properties to keep in mind include:

- Specific gravity. The weight of a material is related to the specific gravity of the material. Generally, the greater the specific gravity, the heavier the material, and the lower the specific gravity, the lighter the material.

- Impact strength. The impact strength of a material can be measured in a number of ways. The Notched Izod Impact test measures a material’s resistance to impact from a swinging pendulum. The key measurement is how much kinetic energy is required to cause fracturing and for fracturing to continue until the material breaks.

- Tensile strength. The tensile strength of a material is defined as the maximum load it can support without failing when stretched divided by its original cross-sectional area.

- Flexural modulus. The flexural modulus of a material is a measure of its ability to resist bending. Materials with a higher flexural modulus are more rigid, while materials with a lower flexural modulus are more flexible.

- Hardness. The hardness of a material is a measure of its ability to resist permanent indentation. While a linear correlation between hardness and mechanical strength can be observed, the hardness of a material is not always indicative of its other properties (e.g., resistance to abrasive, scratches, and wear). As such, it should not be the sole factor when choosing a material for a product.

- Thermal stability. The heat deflection temperature (HDT)—also referred to as heat distortion temperature—of a material is the temperature at which it will deform under a specified load. The material chosen for a part or product should have an HDT that is above the intended application’s maximum operating temperature range.

- Cost. The cost of the material affects the overall cost of the injection molding project. It is important to find a balance between the application requirements and budgetary restrictions where possible.

Partner With Port Erie Plastics for Your Plastic Injection Molding Needs

Looking for a partner for your next plastic injection molding project? Turn to the experts at Port Erie Plastics. We can handle various part designs, construction materials, and production sizes. Check out our case studies for examples of past projects. For additional information about our thermoplastics selection or injection molding capabilities, contact us today. To discuss your project requirements with one of our team members, request a quote.

Comments are closed