When To Consider Injection Molding Plastic for Your Project

Plastic injection molding is an efficient and cost-effective way to fabricate custom parts and components from thermoplastics. It is a versatile method used to produce various products, from medical devices to toys. This process is a great option for many applications, but it’s important to understand the considerations and benefits of this process before making a decision.

This blog post will discuss when to consider injection molding plastic for your project, its uses and applications, and the benefits of custom plastic molding.

What Is Injection Molding Plastic?

Injection molding involves injecting molten plastic resin into a pre-formed custom steel mold to create a desired shape or form. The molded parts are then cooled and ejected, producing highly accurate and consistent components with almost no material waste. Injection molding tends to have the highest cost for tooling compared with other ways to process plastic, but it has the lowest piece prices.

Benefits

Custom plastic molding offers many advantages over other manufacturing methods, including cost-effectiveness, accuracy, repeatability, and the ability to create complex designs. Additionally, injection molding plastic is a great option for creating custom product colors or finishes. It also offers a fast turnaround time for production, enabling companies to quickly get their products to market.

Applications

This process’s high accuracy and repeatability make it an attractive manufacturing solution for many industries that manufacture large quantities of products requiring precision in size and shape. Additionally, it is a cost-effective method because of the speed at which it can mass-produce components with intricate details.

Because of its advantages, injection molding plastic is ideal for many applications, including medical devices, toys, packaging, automotive parts, electronics, electrical components, and consumer goods.

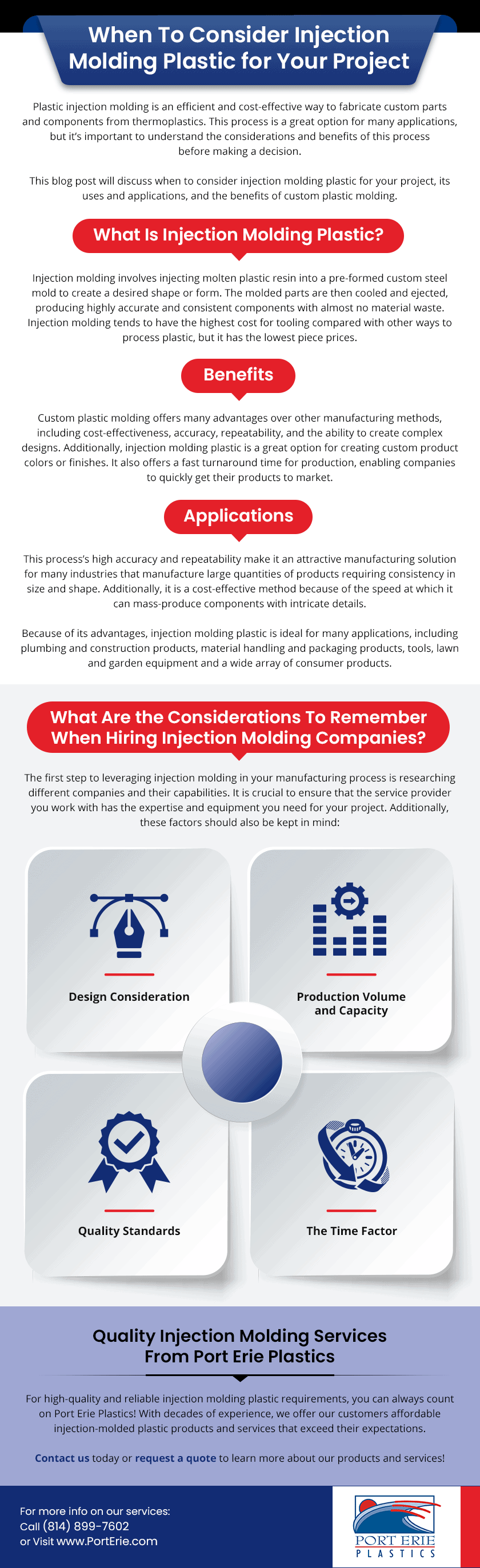

What Are the Considerations To Remember When Hiring Injection Molding Companies?

The first step to leveraging injection molding in your manufacturing process is researching different companies and their capabilities. It is crucial to ensure that the service provider you work with has the expertise and equipment you need for your project. Additionally, these factors should also be kept in mind:

Design Consideration

Consult an experienced plastics designer when preparing your product for injection molding. This will ensure that all components are crafted in a way that can be efficiently and cost-effectively produced. Ideally, involving both the designer and the molder from the beginning stages of a project is best.

Production Volume and Capacity

What is the expected production volume for your project? Knowing this will help you select an injection molding company that can handle both short-run and high-volume projects. It will also help determine the cavitation needed for the mold.

Quality Standards

Does the injection molding company have quality control measures to ensure that parts are produced consistently and accurately? Service providers committed to quality and manufacturing excellence are more reliable in producing components at the highest quality and delivering projects on time.

The Time Factor

It is equally important to communicate your project timeline with your selected injection molding company to ensure that production is completed on schedule. Manufacturers that offer fast turnaround times also help you gain a competitive advantage in the industry.

Quality Injection Molding Services From Port Erie Plastics

For high-quality and reliable injection molding plastic requirements, you can always count on Port Erie Plastics! With decades of experience, we offer our customers affordable injection-molded plastic products and services that exceed their expectations.

Contact us today or request a quote to learn more about our products and services!

Comments are closed